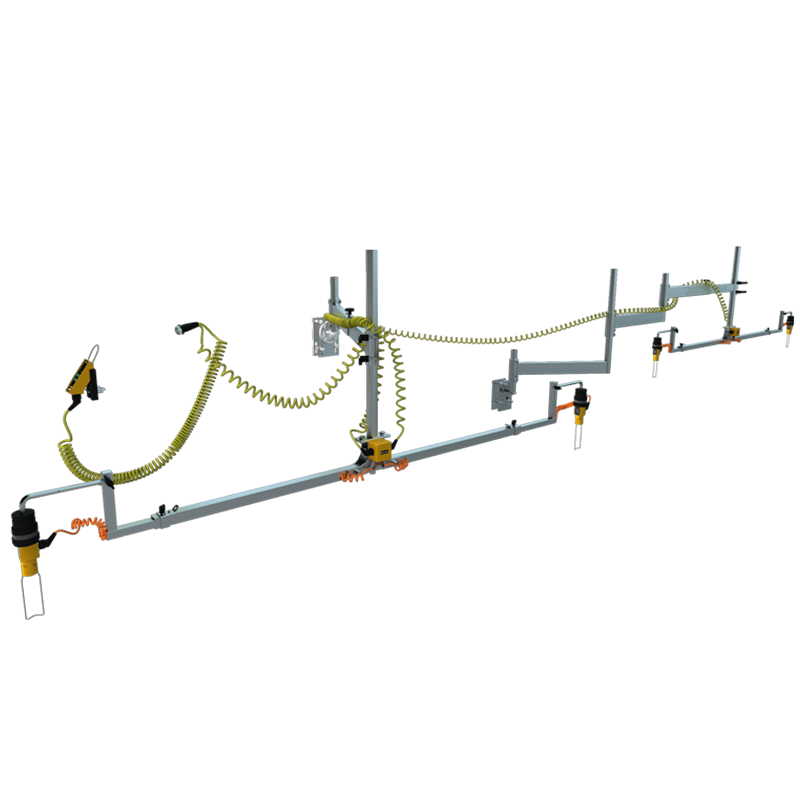

Asphalt Paver Averaging Beams & Ski Sensors

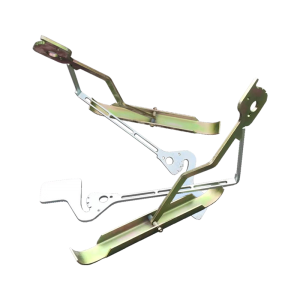

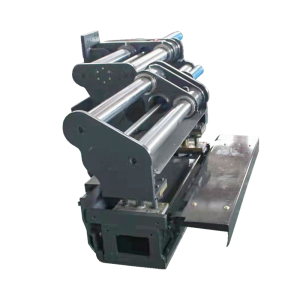

Asphalt pavers use sophisticated electronic sensors to precisely control mat thickness and contour during paving. Two key components are averaging beams and ski sensors. Averaging beams employ ultrasonic or sonic sensors to measure the height of the asphalt mat behind the screed. They take multiple readings across the width of the screed and average them to determine mat thickness. This data automatically adjusts the screed angle to maintain the desired profile. Ski sensors are located in front of the screed and detect grade variations ahead. There are two main types - sonic and mechanical. Sonic ski sensors use sound waves to provide a constant, real-time scan of the surface. They can take hundreds of readings per second to detect even minute changes in elevation. This high-resolution data allows the screed to make smooth, constant adjustments. Mechanical ski sensors use a wheel that rolls along the base surface. They physically sense and compensate for any dips, bumps or inconsistencies. Mechanical skis are simpler and more rugged.

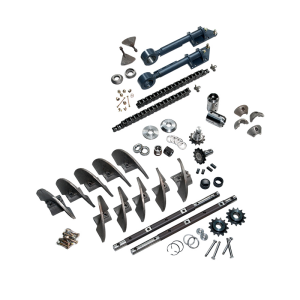

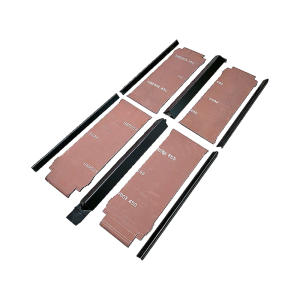

Crafts is able to provide asphalt paver averaging beams with sonic ski sensors for VOLVO, VOGELE, DYNAPAC, CAT, etc. Meanwhile, the OEM asphalt paver mechanical grade ski sensors could also be able to supplied. Most of time, we could confirm the mechanical grade ski sensors size according to your machine model and produced year, or the parts number. Therefore, if you need to ask us the paver and milling machine control panel, please do remember show us the parts number, your machine model and its name plate. It will be helpful a lot.