Products

-

Explore The Depths Of The Swamp Truck You Don’t Know About

With a swamp excavator, you can take on wetland cleanup projects with confidence, knowing you have the right equipment to get the job done efficiently. Experience the power and versatility of this amphibious excavator and revolutionize the way you manage swamps and wetlands. Embrace the future of land cleanup with a swamp excavator today!

-

Undercarriage Parts for Asphalt Paver & Road Milling Machine

The asphalt paver and road milling machine undercarriage parts include track chain, sprocket, idler, track adjuster, track rollers, carrier rollers, rubber track pads. These parts work together to allow the paver to move along a job site and support the weight of the entire machine during operation.

-

Asphalt Paver Screeds Hydraulic Extending Screed Extension Mechanical Extending Screed Extension

The extending screed is an important component on an asphalt paver that allows the screed system to be adjustable to varying paving widths. The extending screed attaches to the ends of the main screed plate to effectively increase the total screed width. It consists of steel screed plates that are connected to the main screed, screed heaters and vibrators to match the main screed system, and a hydraulic mechanism to extend and retract the screed plates.

-

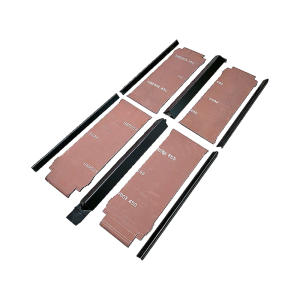

Asphalt Paver Screed Bottom Plate Assembly including Heating Rods Screed Plates and Tamper Bars

The screed bottom plate, along with the main screed plate assembly, makes up the screed plate assembly on an asphalt paver. The screed bottom plate attaches to the underside of the main screed plate and together they help level, smooth, and compact asphalt material as it leaves the paver.

-

Paver Control Panel

The paver control panel is the heart of an asphalt paver, consolidating all controls onto a single interface to streamline operation. Located on the side and rear of the paver, the control panel allows operators to monitor and adjust all paving functions including steering, material flow, screed, augers, and temperature.

-

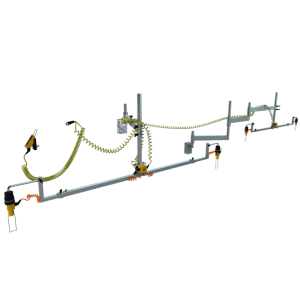

Asphalt Paver Averaging Beams & Ski Sensors

Asphalt pavers use sophisticated electronic sensors to precisely control mat thickness and contour during paving. Two key components are averaging beams and ski sensors. Averaging beams employ ultrasonic or sonic sensors to measure the height of the asphalt mat behind the screed.

-

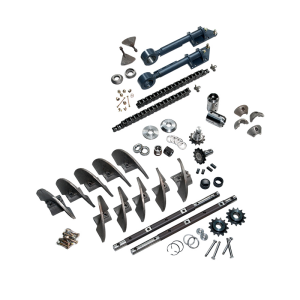

High Quality Aphalt Paver Auger Assembly

The auger is a key component of an asphalt paver. it is a helical screw or worm housed within the frame of the paver. It rotates horizontally to gather asphalt material from the hopper at the front of the paver and transport it to the screed at the rear for extruding the asphalt onto the roadway.

-

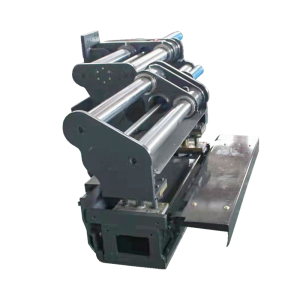

Driving Shaft Assembly for All Famous Brand Asphalt Pavers

The asphalt paver driving shaft provide an optimal guide of the conveyor chains. It is the driving mechanism for the conveyor chains with scrapers to operate longitudinally for conveying the asphalt mix during the operation of the paver.

-

Conveyor Chains for All Famous Brand Asphalt Pavers

Asphalt paver conveyor chains are a critical component in the process of paving roads and other surfaces with asphalt. The conveyor chains are responsible for moving the asphalt mix from the hopper to the screed, which distributes the mix evenly across the surface being paved.

-

Conveyor Floor Plates for All Famous Brand Asphalt Pavers

Crafts asphalt paver conveyor floor plate is designed to provide efficient and reliable performance, which meet the demands of the asphalt paving industry for different brands and model asphalt pavers.

-

Durable Bottom Rollers & Top Rollers for Tough Construcion and Mining Tasks

Crafts track rollers and carrier rollers are according to the standard of OEM to manufacture. The main pin shaft of our roller is made by round steel, and the shell are forged by special steel. Both of the shaft and the shell are hardened by the heat treatment deep to 6mm and up to the HRC 56° around, to make sure they are hard enough to cover the bad work condition.

-

Grass cutter

As an ideal tool for cutting grass, brushes and small trees, skid steer brush cutter is widely used in farm and municipal works. We take high strength steel Q355 to build the brush cutter body for solid structure, and take the NM400 steel to make the sharp and durable cutting blade.