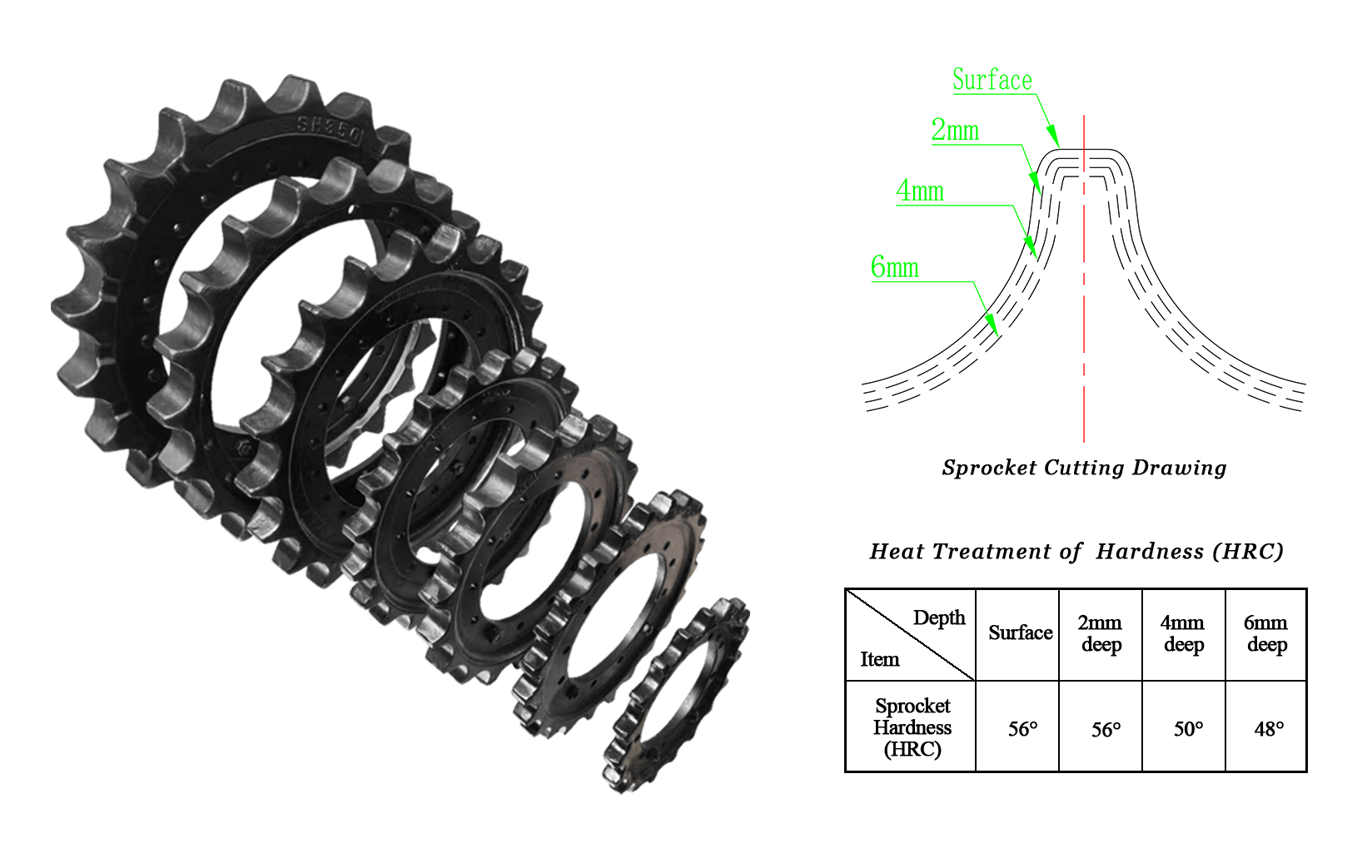

Reliable Performance with Our Sprockets and Segments

Crafts sprockets and segments are manufactured according to the standard of OEM. All of Crafts sprockets and segments are casted by special steel, to make sure they are strong enough to bear and transmit the hydraulic power. And they are made in four processes: first, make mound, cast to produce sprockets and the segments, this process help us get the rough sprockets and segments ; second, grind all the sprockets and segments surface, this process make the sprockets and segments surface clean; third, adopts the intermediate frequency heat treatment on the sprockets and segments teeth surface, to the depth 4mm-6mm, hardness HRC45°-55°, this process make the teeth of the sprockets and segments reach the best wear-resistance and prolong life time to maximum extent; at last, machine all the sprockets and segments surface to the specific measurement, then we got the perfect fit sprockets and segments.

|

Brand |

Model |

|

Komatsu |

PC20, PC30, PC40, PC50, PC60, PC100, PC120, PC200, 20HT, PC220, PC300, PC360, etc. |

|

Sumitomo |

SH60, SH120A, SH200, SH220, SH260, SH280, SH300, SH340, SH350, SH430, SH580, etc. |

|

Hitachi |

EX30, ZX40, ZX55, ZX70, EX100, EX200, ZX230, ZX240, EX300, ZX330, ZX360, etc. |

|

Daewoo |

DH5, DH220, DH280, DH300, DH320, DH330, DH360 |

|

Kobelco |

K904, K907, SK40, SK50, SK60, SK100, SK120, SK200,SK220, SK230, SK250, SK300, ect. |

|

Caterpillar |

CAT303.5, CAT306, CAT307, CAT312, CAT315, CAT320, CAT325, CAT330, CAT336, CAT349, etc. |

|

Volvo |

EC55, EC140, EC210, EC 240, EC290, EC360, EC480, EC700, EC750, EC950,etc. |

|

Bulldozer |

D20, D30, D31, D3D, D4D, D50, D6D, D60, D65, D7G, D80, D85 |

Having wide choice range, the sprockets and segments are applicable to special model of crawler type excavators and bulldozers from 0.8t to 100t. They are widely applied in excavators and bulldozers of Caterpillar, Komatsu, Hitachi, Kobelco, and Hyundai etc. The following is parts of what brands and models that our sprockets and segments can be perfect fit.