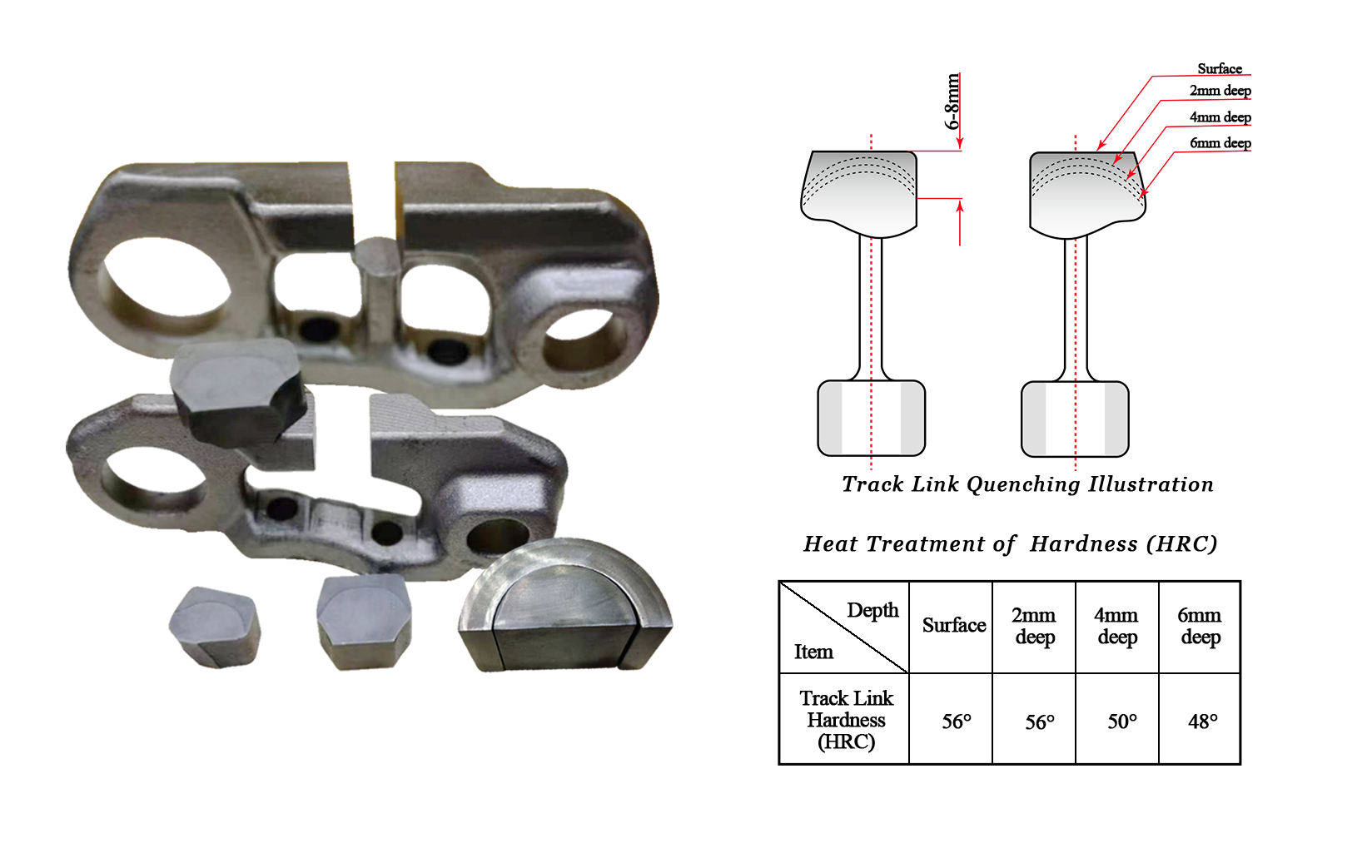

Track Links

Crafts track links are manufactured according to the standard of OEM. All of Crafts track links are forged by special steel 35MnB. Comparing to other track links which made of 40MnB or 40Mn, our track links are better in toughness and abrasive resistance.

Machining processes are the normal producing process to all the track links, including grinding the surface, drilling the bolt hole, smoothening bolt surface, machine pin hole to specific size. Besides the material factor, the heat treatment is also the key process to ensure the track links quality. Crafts takes 2 heat treatment process for each track link: first, thermal refining – whole link hardening HRB 270° - 297°; second, mid frequency hardening – track links surface heat treatment HRC52° - 56°, deep to 6mm.

After the two heat treatment processes, our track links become much tougher and more durable, which bring you longer service life and better cost-effective.

Track links are also called track chains, usually, there are 4 connection holes on a track plate and another 2 cleaning holes in the center. The cleaning holes are able to clear earth of the plate automatically. Two neighboring plates have stacking part. To avoid stone pieces stuck in between and cause damage, track plates with triangle-shape can be used if an excavator runs on wet ground, because the triangle-shape can press the soft ground and increase supporting capacity. Having wide choice range, crafts track links are applicable to special model of crawler type excavators and bulldozers from 6t to 100t. They are widely applied in most famous brands excavators and bulldozers, such as Caterpillar, Komatsu, Hitachi, Kobelco, and Hyundai etc.